When purchasing that brand new luxury handbag or designer pair of shoes, money is no object in the pursuit of quality – and visiting our favourite fashion houses to lay our hands on the very finest goods is a pleasure quite unlike any other. But as the popularity of 3D printing continues to grow, it’s begging the question as to whether it could be set to revolutionise the way we source the items we want, as well as the ways in which our preferred designers produce them. Could this really be the future of luxury shopping?

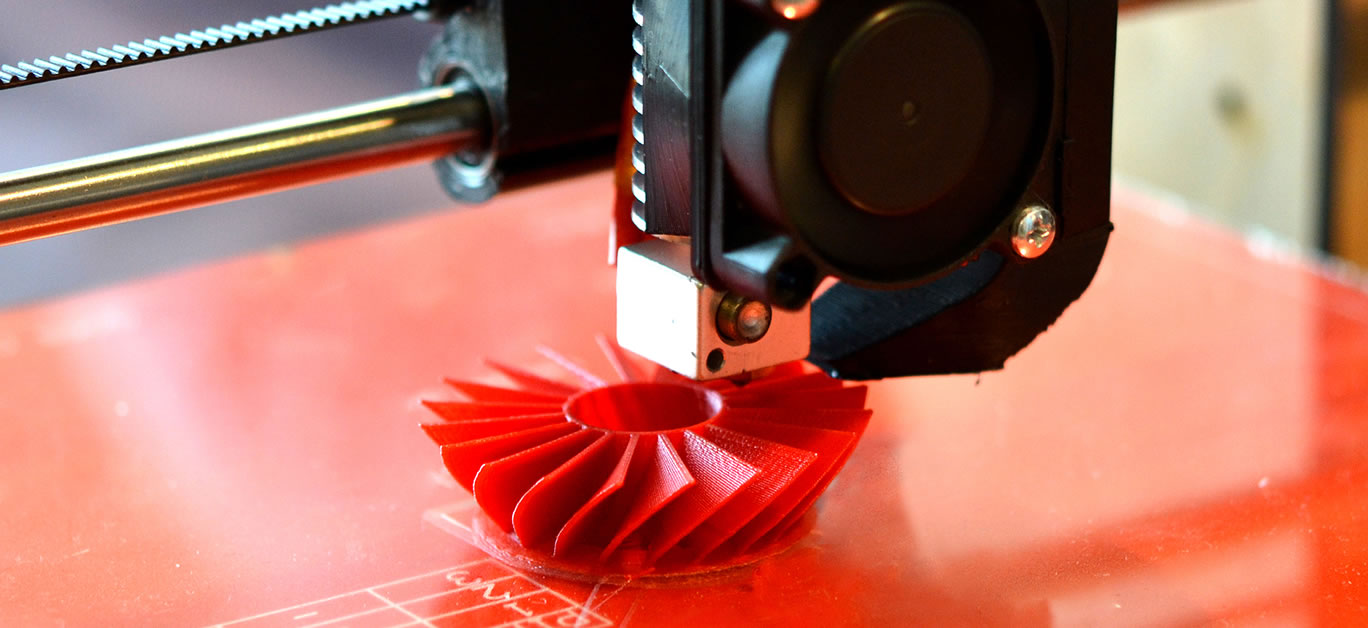

For some die-hard designer fans, the initial answer might be ‘no’ – but the truth is that 3D printing can actually be a great option for creating and sourcing luxury goods. The technology behind it has come a long way in recent years, and there are now many high-end 3D printers available that have some rather impressive capabilities. With the right printer and materials, it’s possible to create products that are just as good or even better as those made with traditional manufacturing methods, and you might be surprised to see the results.

One of the benefits of 3D printing is that it allows for greater customisation than traditional methods. If you want to create a luxury item that is truly unique, then 3D printing is a great option, as it will allow you to design your product exactly how you want it to look and feel, safe in the knowledge that no one else will have anything like it. Every detail can be accounted for and perfected before the final product is made – which means that any flaws in the design can be corrected before the item is even produced.

This attention to detail ensures that your product will be of the highest quality possible, ticking all the right boxes when it comes to luxury. So, if you thought the only place to get high-end goods was from a designer boutique, then it might be time to open your mind.

Luxury goods are all about attention to detail. From the materials used to the craftsmanship, every element must be of the highest quality – which is why 3D printing is such a game changer for the industry. With traditional manufacturing methods, it can be difficult to achieve the level of precision that is required for luxury products, and even small imperfections can be costly, both in terms of money and reputation. But with 3D printing, you can be sure that your product will meet the highest standards of quality, no matter what.

The level of precision possible with 3D printing is simply not possible with other methods, and it’s precisely this fact that has been garnering attention over recent years. While we’re still a long way from 3D-printing all of our goods, in a few years, we could regularly be sourcing items in such a way – and for the luxury goods industry, it’s an exciting time.

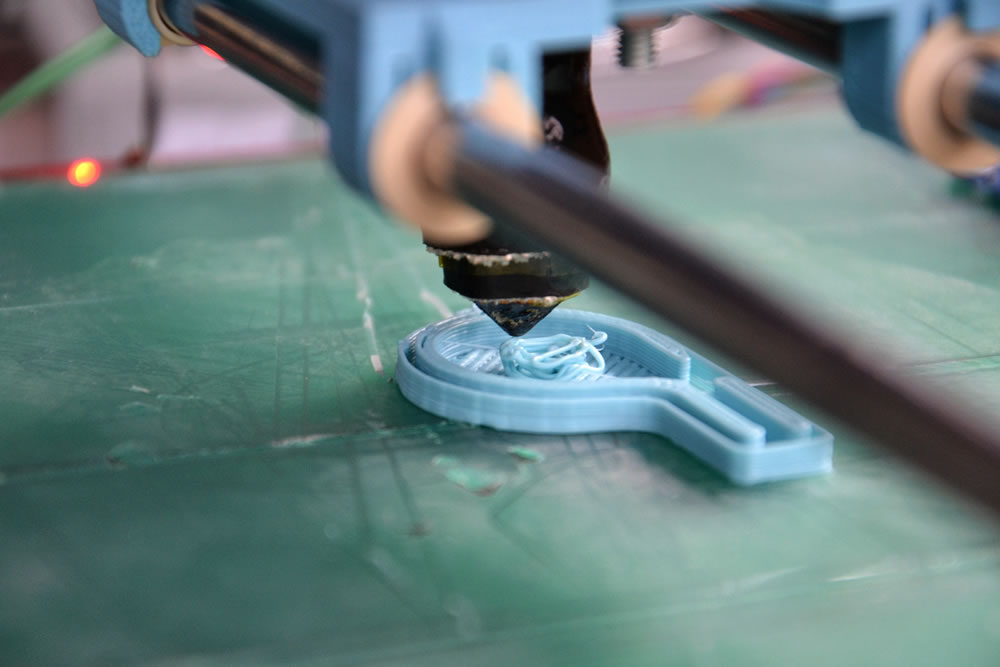

Most 3D-printing technology is not quite advanced enough yet for the manufacturing of soft materials like fabrics, so for those looking for bespoke luxury fashion, there’s still some way to go before this becomes a complete reality – but the experts are working on bringing this possibility to fruition, and some designers are already using 3D printing in the creation of their clothing lines regardless. One notable example is Danit Peleg, an Israeli fashion designer who was the first person ever to create a full collection using 3D printers – which could, as technology continues to move forward, pave the way for others to follow suit.

For hard materials like metals and plastics, 3D printing is an excellent option already, and many high-end companies are currently using 3D printers to create products like jewellery and watches.

3D-printers offer some pretty impressive possibilities on their own, but when paired with innovative manufacturing software, these become even more exciting. Products such as Katana Manufacturing Software can help to streamline the entire process, from design to production, as well as helping to keep track of inventory and orders and automating some of the more tedious tasks involved in manufacturing.

With this particular product, you can track every aspect of your production line and make sure that everything is running smoothly. 3D printing offers the precision and customisation required to create the very finest luxury goods, while Katana takes care of the rest – from quoting and order management to production planning and scheduling – and with this combination, you can be sure that your products will be of the highest quality possible, and that your business will run smoothly and efficiently.